Trackless mobile grow racks, also known as automated mobile grow systems or autonomous mobile cultivation systems, are innovative solutions used in indoor farming to optimize space and increase productivity. Unlike traditional mobile grow racks, which require tracks or rails for movement, trackless systems utilize advanced technology to move the racks autonomously.Trackless mobile grow racks are our latest design. The biggest feature of trackless mobile grow rack is that there is no track in the middle of the frame, which is more convenient for cleaning.

We're here to help: Easy ways to get the answers you need.

Trackless mobile grow racks, also known as free-moving or omnidirectional mobile grow racks, are a type of system designed to optimize space utilization and provide flexibility in indoor farming operations. These racks are equipped with specialized wheels that allow them to move in any direction without the need for tracks or fixed pathways.

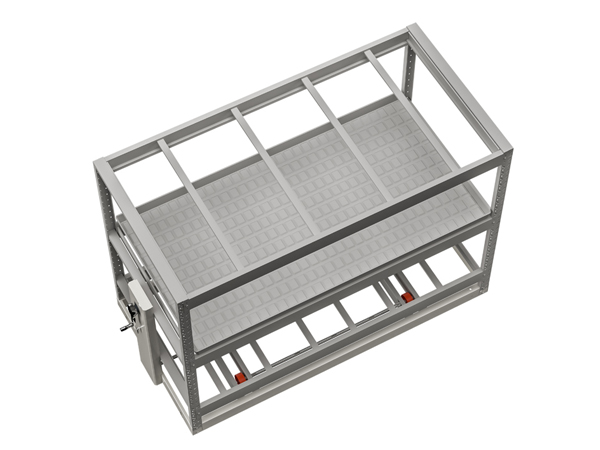

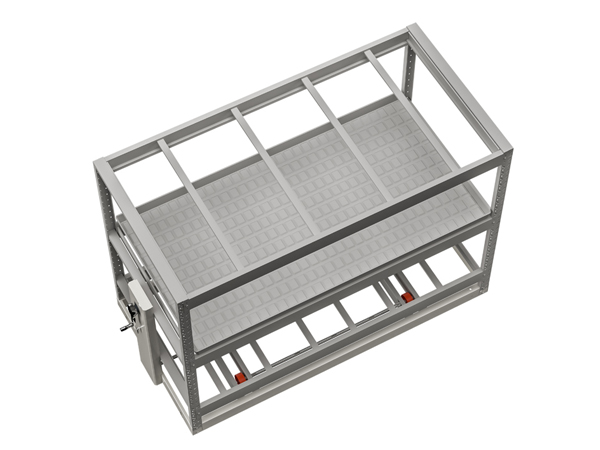

Rack Structure

The mobile grow racks consist of shelves or trays that hold the plants. These racks are designed to be sturdy and capable of supporting the weight of the plants, lighting systems, and other necessary equipment.

Autonomous Control System

The heart of trackless mobile grow racks is an autonomous control system. This system comprises sensors, software, and control units that govern the movement and operation of the racks. It enables precise control and coordination of multiple racks within the cultivation space.

Electric Motors and Wheels

Trackless mobile grow racks are equipped with electric motors and wheels. These motors, controlled by the autonomous control system, provide the necessary power and propulsion for movement. The wheels are designed to operate smoothly on the flooring surface of the cultivation area.

Positioning and Navigation

The autonomous control system uses various positioning and navigation technologies to determine the position and orientation of the mobile racks. This can include technologies such as cameras, lasers, or radio-frequency identification (RFID) systems. By accurately detecting the position of the racks, the system can plan and execute their movement effectively.

Path Planning and Optimization

The autonomous control system utilizes sophisticated algorithms to plan and optimize the movement of the mobile grow racks. It takes into account factors such as the layout of the cultivation area, the position of other racks, and any obstacles in the path. The system plans the most efficient routes for the racks to move, ensuring optimal space utilization and minimizing the risk of collisions.

Integrated Systems

Trackless mobile grow rack systems often integrate other components for enhanced functionality. These may include climate control systems, irrigation systems, and lighting systems. The autonomous control system coordinates with these integrated systems to maintain ideal growing conditions for the plants as the racks move.

Monitoring and Data Collection

The autonomous control system continuously monitors the growing environment and collects data on parameters such as temperature, humidity, light intensity, and nutrient levels. This data is analyzed to make informed decisions and adjustments to optimize plant growth and resource utilization.

|

Size |

High: 8ft/10ft/12ft/14ft/16ft Width and depth: 4ft*4ft/6ft*4ft/8ft*4ft |

|

Layer |

One base + growing tier + one tier for light |

|

Structure |

Knock-down (column will be pre-assemble when shipping) |

|

Volume |

1.6cbm/unit (column pre-assemble) 1.0 cbm/unit( all knock-down packing) |

|

Growing tier |

1-4growing tier.(According to customer require) |

|

Load |

200kg--450kg/layer |

|

Fish |

white with Anti-Fungal and Anti--Microbial finish |