Grow racks, also known as cultivation racks or plant racks, are specialized shelving systems designed for indoor farming or vertical gardening. They provide an efficient and space-saving solution for growing plants in a controlled environment. The performance of grow racks is dependent on the careful consideration of factors such as space utilization, structural integrity, lighting systems, climate control, irrigation, automation, workflow, plant health, scalability, and energy efficiency. By addressing these factors, growers can create an optimized growing environment that promotes healthy plant growth, high yields, and efficient operations.

We're here to help: Easy ways to get the answers you need.

Grow racks are specialized shelving units used for growing plants indoors or in a controlled environment. They are designed to maximize growing space and to provide the right conditions for plant growth, such as adequate light, temperature, humidity, and nutrient delivery.

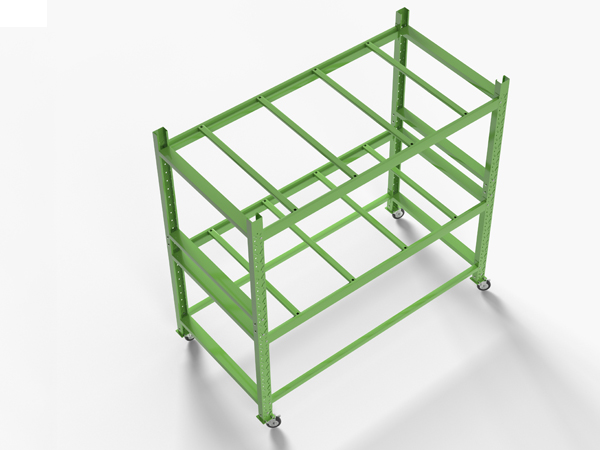

Grow racks can be stationary or mobile, and come in various sizes, shapes, and designs to suit different growing needs. They may have shelves or trays for holding pots, hydroponic systems, or other growing containers, and may be equipped with lighting and climate control systems.

Grow racks are used in a variety of settings, including residential gardens, commercial greenhouses, and indoor hydroponic growing systems. They offer several benefits, including increased growing space, improved plant health and growth, and more efficient use of light and nutrients.

The performance of a grow rack depends on several factors, including the type of plants being grown, the lighting and nutrient system used, and the overall environment and conditions of the grow space. To maximize the performance of a grow rack, growers should take measures to maintain appropriate growing conditions, provide adequate light and nutrients, and implement good growing practices.

Space Utilization

Grow racks should maximize the use of available space by utilizing vertical growing techniques. The design and layout of the racks should allow for optimal plant density while providing sufficient space for each plant to grow and receive adequate light.

Structural Integrity

The quality and sturdiness of the grow rack structure are crucial for supporting the weight of plants, equipment (such as lighting systems and irrigation setups), and any additional accessories. The racks should be durable, stable, and capable of withstanding the demands of plant cultivation.

Lighting Systems

The type, quality, and positioning of the lighting systems within the grow racks significantly impact plant growth and yield. Efficient and adjustable lighting fixtures, such as LED grow lights, should be incorporated to provide the appropriate spectrum, intensity, and duration of light for different stages of plant growth.

Climate Control

Grow racks may integrate climate control systems to regulate temperature, humidity, and airflow within the cultivation space. Maintaining optimal environmental conditions promotes healthy plant growth and helps prevent issues like mold, pests, or diseases.

Irrigation and Nutrient Delivery

The grow racks should facilitate efficient and precise irrigation and nutrient delivery systems. Proper water distribution, nutrient availability, and pH balance are essential for plant health and productivity. Automated or controlled irrigation systems can optimize water usage and nutrient uptake.

Automation and Control Systems

The efficiency and effectiveness of automation and control systems play a significant role in the performance of grow racks. Integrated sensors, monitoring devices, and control units should accurately measure and regulate environmental factors, such as light, temperature, humidity, and nutrient levels. This automation enables precise control, reduces human error, and provides real-time data for analysis and adjustments.

Accessibility and Workflow

The design of grow racks should facilitate easy access to plants for maintenance, harvesting, and inspections. Considerations like shelf height adjustment, ergonomic design, and ease of movement contribute to efficient workflow and minimize the time and effort required for routine tasks.

Plant Health and Disease Control

The design and functionality of grow racks should prioritize plant health and disease control. Adequate spacing between plants, proper airflow, and isolation mechanisms in case of pest or disease outbreaks can help prevent the spread of pathogens and ensure overall plant well-being.

Scalability and Flexibility

Grow racks should be scalable to accommodate expansion or changes in cultivation needs. Modular designs that allow for easy addition or removal of shelves or tiers enable growers to adapt to evolving requirements. Flexibility in configuration and repositioning of the racks also enhances operational efficiency.

Energy Efficiency

Grow racks should aim for energy-efficient operations, especially regarding lighting and climate control systems. Opting for energy-saving technologies and properly insulating the cultivation space can reduce energy consumption and operational costs.

Item

Grow Rack

Size

H2440/3050/3660/4270/4880mm

also the size could be customized)

Thickness

0.8-1.2mm cold rolled steel

Surface

Electrostaic Powder coating

Warranty

10 years

Color

RAL color or customized

Structure

Knock-down

Usage

Farm, warehouse, greenhouse, factory, and other commercial

Product range

Mass shelf. compact rack, mobile file rack, goods shelf, book shelf, safe box, file cabinet, etc.

Remark

OEM/ODM accepet.

W2450*D1220mm(standard size,

W8*D4ft,W4*D4ft

H6/H8/10/12/14/16ft